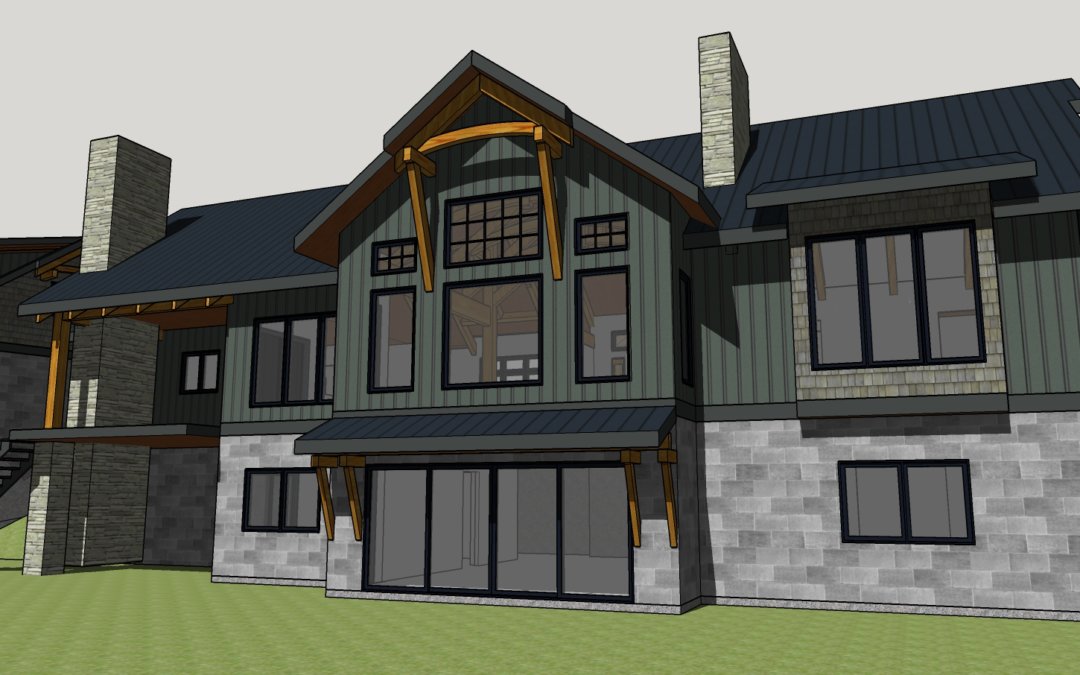

Wall Panel and Timber Assembly

Another custom hybrid timber frame prefabricated house package was recently shipped to Washington State, USA from Tamlin’s facility in British Columbia, Canada. This custom is a 3,870 square foot home with 1,550 square foot garage and loft, features Tamlin’s West Coast solid Douglas Fir Post & Beam structure which was precut in our factory, then shipped and assembled on site. Tamlin has been working with the owner and a local framing crew over the last number of months to prepare for the arrival of the house package. When it arrived, the foundation was already complete, and the trucks could be unloaded as soon as they arrived on site.

Depending on each building project, Tamlin offers an option to send a qualified supervisor to help with the timber assembly. On this project, a supervisor was sent to the job site to help guide and train the local crews to make the timber assembly quick and easy. A crane or “zoom boom” is typically used on site to hoist the timber components and prefabricated wall panels into place. Sometimes part of the timber structure such as the “bents” or timber trusses are assembled first, and then lifted into place.

On day two, you can see how quickly the timber trusses, wall panels, and roof structure have come together! Simple tools such as “come along winches” and rubber mallets come in handy to gently bring the timbers into position. Tamlin even predrills holes when necessary and supplies special engineered screws or hardware to make sure you have everything you need on site. Having the timbers pre-stained at the factory helps to protect the Douglas Fir and keep the timbers looking like new.

The key to ensuring that the process on site goes smoothly is all the preparation work that Tamlin does ahead of time. For our export projects to the USA, Tamlin typically works with the homeowner, engineer and local builder months in advance to ensure that each stage of the building process is “checked off” with the right level of communication and timing, so by the time the house package arrives on site construction can continue without delay. All the little details including engineered hardware for “seismic” requirements were dealt with on this project due to its location on the West Coast of Washington State. When the materials package arrives on site, and the trucks are unloaded, Tamlin even includes “water proof drawings”, and a complete assembly kit with “bill of materials” and “packing lists” which correspond to clearly labelled packages.